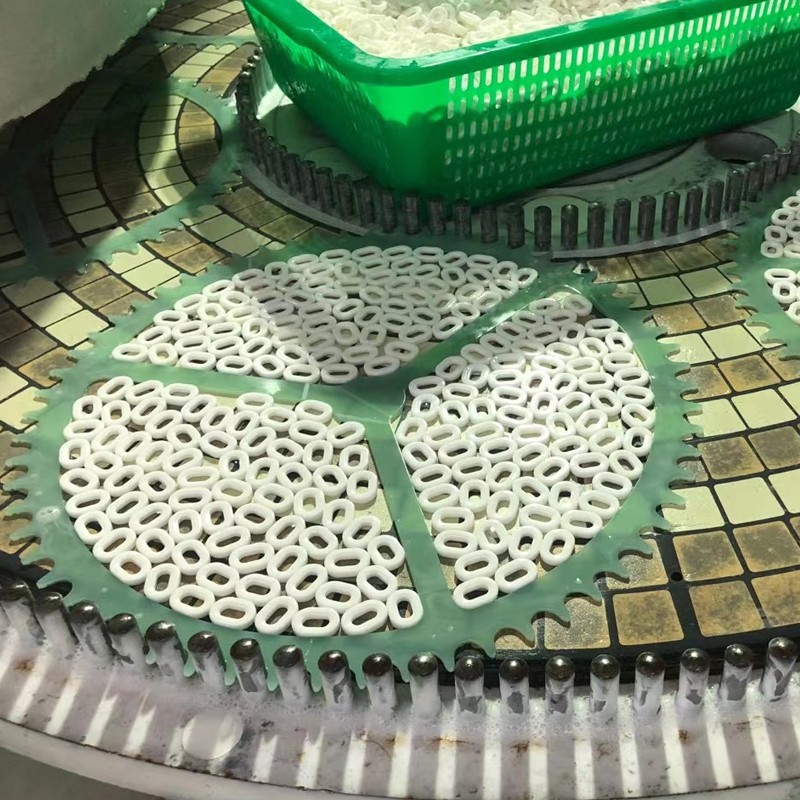

Product application: it is suitable for double end grinding of automobile engine parts, air conditioner compressor parts, hard alloy cutting tools, PCD,PCBN cutting tools, alumina, zirconia ceramic products, precision bearings, hydraulic pneumatic components, cutting tools, crystal, gems, silicon and other products.

Product features: Common problems in plane grinding are, low grinding efficiency (grinding immobility), short service life of the grinding disc, the precision of the grinding parts is not up to standard, workpiece scratches, workpiece smoothness and surface blackening and so on.

Product Description:

1. Product classification: ceramic superhard grinding disk is divided into ceramic diamond grinding disk and ceramic CBN grinding disk.

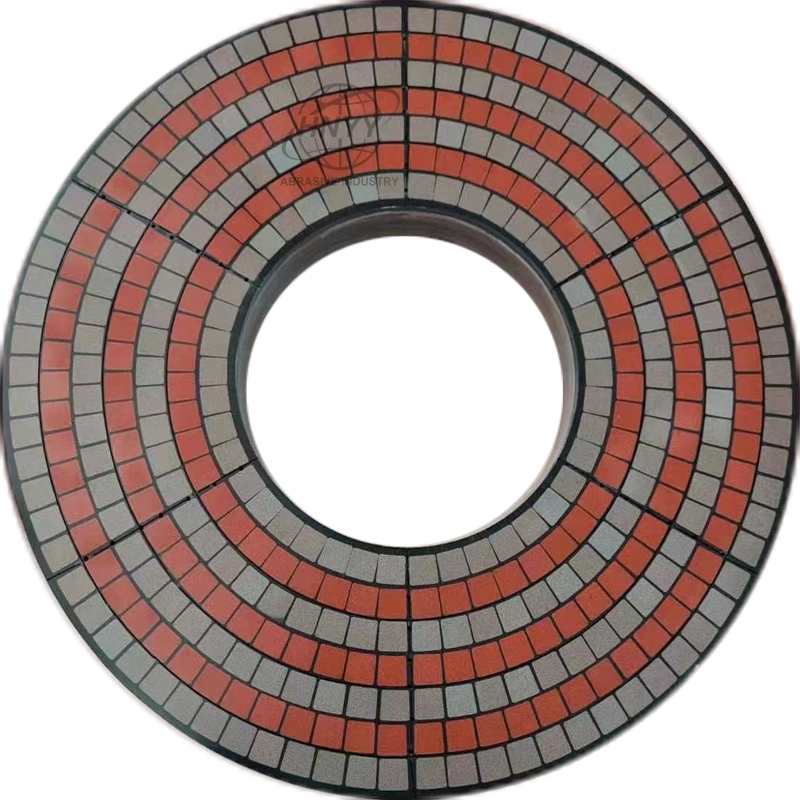

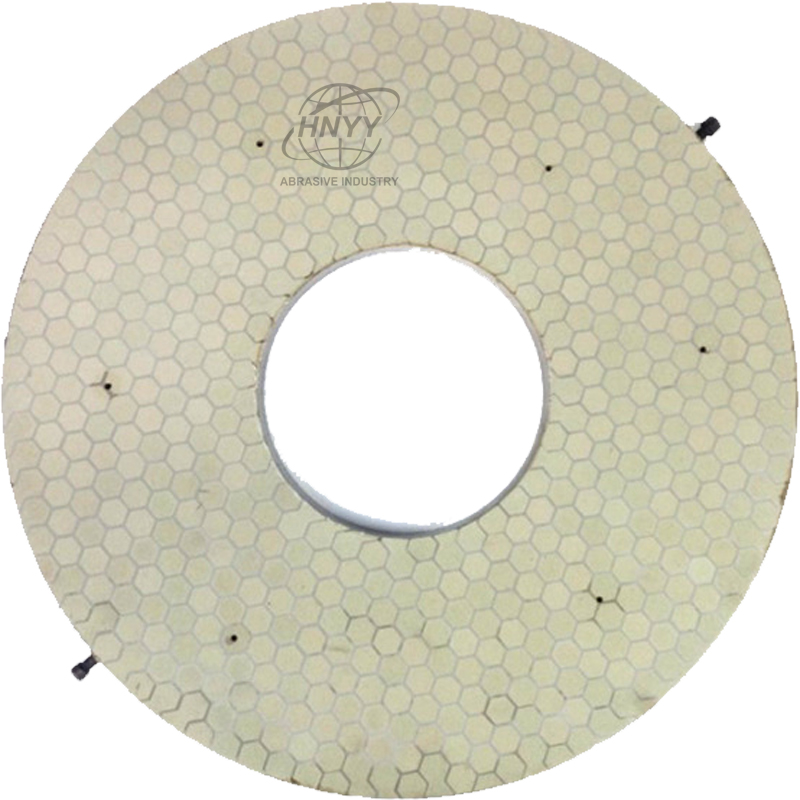

2. Product structure: ceramic grinding disc is made of grinding disc matrix and super hard grinding block by epoxy resin adhesive bonding, super hard grinding block shape, round, hexagonal, fan-shaped, square.(Can be customized according to customer requirements)

3. Product application: it is suitable for double end grinding of automobile engine parts, air conditioner compressor parts, hard alloy cutting tools, PCD,PCBN cutting tools, alumina, zirconia ceramic products, precision bearings, hydraulic pneumatic components, cutting tools, crystal, gems, silicon and other products.

4. Product features: Common problems in plane grinding are, low grinding efficiency (grinding immobility), short service life of the grinding disc, the precision of the grinding parts is not up to standard, workpiece scratches, workpiece smoothness and surface blackening and so on.According to the above common problems, our chief engineer refined the formula, controlled the raw materials, optimized the production process and matched the scientific management system, so that our products have more advantages in the market.In the workpiece end face grinding precision up to 2μm, the finish Ra0.02, part of the workpiece to achieve mirror effect.

5. Product advantages: 1. "High Grinding efficiency" selection of high-quality super hard abrasive with reasonable abrasive particle size to improve the sharpness of the grinding disc.

2. "Long service life" makes the grinding disc have reasonable hardness, longer time in a sharp state to reduce dressing frequency, improve the purpose of service life.

3. "Good Shape Retention" Our company can make the grinding disc in a smooth state for a long time by optimizing the formula of the grinding disc and providing the workpiece grinding scheme, so as to achieve the accuracy consistency of the workpiece.

6. Supporting equipment: Xinxiang Skaif, Xinxiang Wanhua, Xinxiang Risheng, Wenzhou Baicheng, Suzhou Herite and other domestic double end grinding machine.South Korea AM, Japan Guangyang, Germany Pete Walter, Britain lamat and other imports of double end grinding machine.

<table class="table"> <thead> <tr> <th scope="col">#</th> <th scope="col">First</th> <th scope="col">Last</th> <th scope="col">Handle</th> </tr> </thead> <tbody>